Greenheart has over two decades’ experience designing and constructing sustainable buildings – plenty of time to build up a tried and tested palette of the environmentally friendly building materials and techniques we use. We’re also open to different approaches and always ready to challenge ourselves, as well as being experienced in a wide range of more traditional building practices.

We understand the detail and expertise required in working with new and innovative building methods, maintaining close partnerships with technicians and industry specialists, in an industry where new developments are happening every day. We are happy to discuss and share our wide ranging specialist knowledge, from insulation and cladding solutions to MVHR Heat Recovery Ventilation or how to get the most from renewables.

There are numerous factors to consider when selecting materials, including control of air and moisture, low toxicity and low embodied CO2, thermal performance, practicality and cost, drying times, ease of application and aesthetic appearance. Whatever we do, we prefer building solutions that have longevity, using products and materials that last the test of time and that you can enjoy without having to replace, refresh or renew.

Where possible we avoid or reduce concrete, steel, virgin aggregates and petrochemicals (plastics) and we never use tropical or uncertified timber. If you prefer Cheltenham over China for your building supplies, we can help you choose and source materials locally from within the UK, where possible, from companies who share our ethical building approach.

For below ground construction like foundations, basements and retaining walls, the available options are typically restricted to more energy hungry or synthetic materials. This is where careful design and collaboration with like-minded consultants can help us to reduce or design-out unnecessary materials.

Frequently used products, materials and methods

Timber frame

Greenheart has always had carpentry and timber frame construction at its core. We enjoy working with wood and appreciate its qualities from a carpenters perspective. The skeleton of the house, a fine balance of elegance and strength is exciting to build and brings great satisfaction to everyone involved.

As a lightweight but durable, renewable material with low embodied CO2, timber also carries insulation within the voids providing great Uvalues for a given thickness of wall, floor or roof.

Benefits:

- Carbon negative

- Renewable resource

- Light weight – easy to transport and erect

- Durable- if detailed and constructed properly

- Easy to cut and fix on site

- Easy to engineer into structurally reliable beams and shapes

- Attractive finish

- Fire resistant

- Allows structure to contain more insulation.

- Dry build – building doesn’t need to dry out

- Possibility of prefab and super fast construction.

- For solid structural timber and cladding we use FSC certified timber and UK grown cladding products.

- Finjoists (FJI) are made from waste timber production with low embodied CO2, available in very long straight lengths available, has a high strength to weight ratio and is easily cut and drilled.

- Laminated veneer lumber like glulam or Kerto

Insulation

The warm coat worn by our buildings: Insulation is, of course, critical to conserving energy. Though not suitable for all applications, natural, recycled and low ‘embodied carbon’ materials are preferred. These include:

- WARMCEL:

- Manufactured from 100% recycled newsprint with fire retardant salts and blown into timber frame cavities, Warmcel has comparable thermal conductivity to Mineral wool. we love this product and are a certified regional installer.

- Foam glass aggregate: Particularly suited to solid ground floor insulation in renovation projects, this product can also be used for new-builds where ground conditions allow.

- Wood fibre: This material is used on almost all of our projects in some form. As an exterior sheathing panel for timber frame, or internal insulation for solid masonry walls.

Hemp, Lime, Cob, straw and Clay.

Precast Hemp block, and Clay plaster feature quite commonly on our material palette, particularly in renovation situations where their inherent moisture management characteristics are extremely beneficial. We have used materials such as straw bale and wet-cast limecrete on numerous projects over the years, but due to practical limitations such as drying time for limecrete in particular, they are often designed out or limited to a ‘fesature element’ by the time we come to build. If you envisage a project where the use of hempcrete, rammed earth, cob or clay is central to the brief. Do get in touch, we’d be more than happy to discuss it!

Airtightness products

We have an excellent track record achieving impressive air test results, which are achieved primarily through careful detailing and installation of correctly specified tapes and membranes. Whichever products are preferred, a joined-up strategy that works in 3D is essential to success.

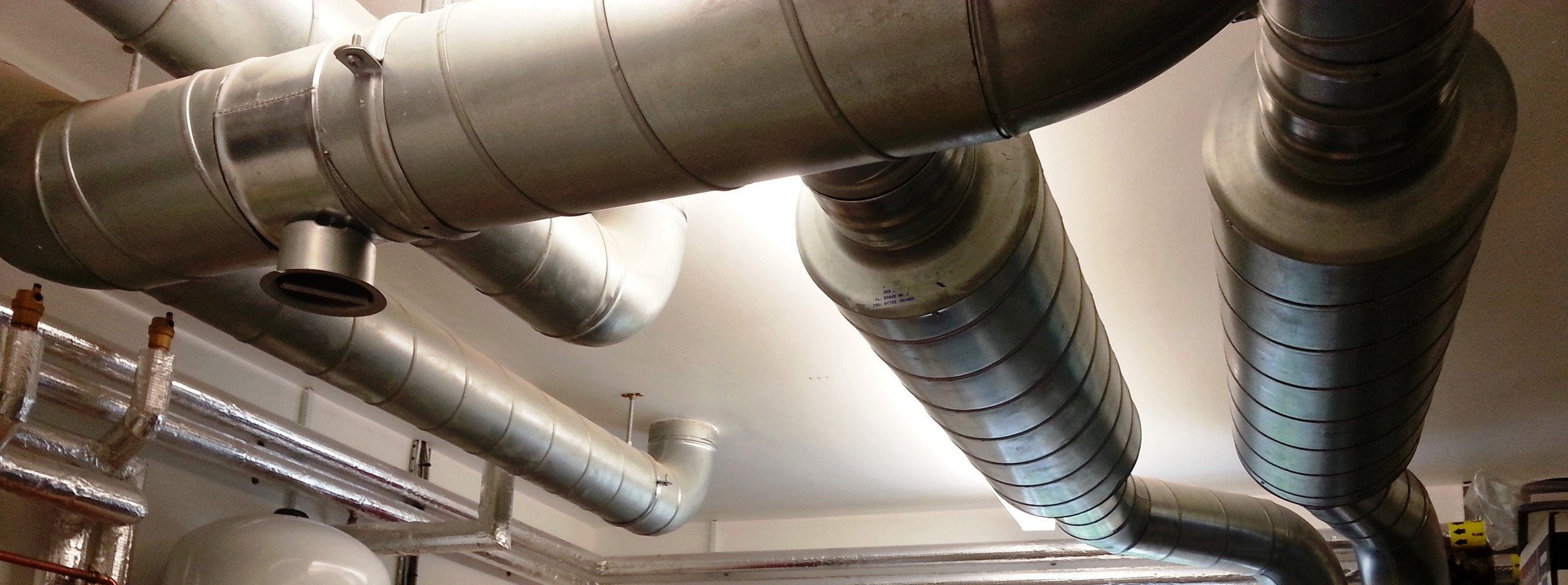

Mechanical ventilation and heat recovery (MVHR) systems

To ensure an MVHR system is efficient, balanced, long-lasting, cost effective and near silent, we believe that using Passivhaus certified MVHR units and high-quality materials for ducting, sealing and insulating is essential. We install the very best systems, designed and supplied by our specialist partners such as Earthwise construction and the Green Building Store

Interiors and landscaping

While our primary focus is on building fabric and energy performance, we take great pride in the many beautiful interiors and landscaping schemes we have created over the years

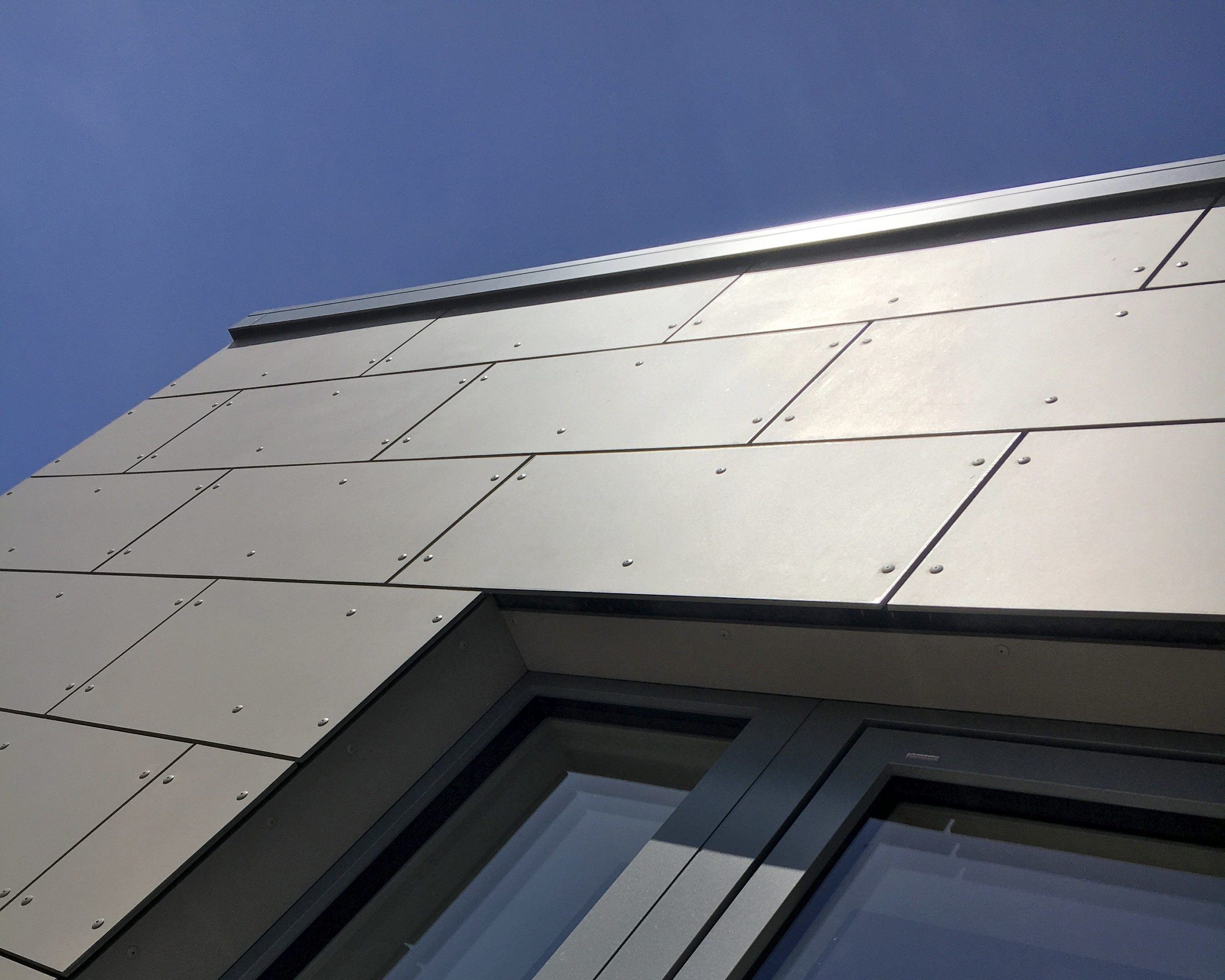

Doors and windows

Always of exceptional thermal performance, often Passivhaus certified. Windows and exterior doors also need to suit the high quality aesthetic our buildings are known for. Either sharp and contemporary, or with a sympathetic, traditional feel. We have used a huge range of different brands over the years and can recommend many that we know will fit the bill. There are also many we haven’t used and would gladly try if you prefer. There’s no substitute for seeing them, touching the handles and feeling their weight and quality so we always recommend visiting a showroom or trade show if possible before making a decision on such a ‘big ticket’ item