Winsley Rd Passivhaus

We were initially approached by the Clients for Winsley Rd, to look at a different plot in Somerset which they were interested in buying. That sale didn’t progress, but when they found the site in Bradford upon Avon, got back in touch and we began working with them on a concept design.

The brief was clear, as a retired couple, they wanted the house to be small, no bigger than necessary to meet their needs, it should be certified PH, should contain no concrete, and an absolute minimum of plastic and other harmful or energy hungry materials (ideally none).

Achieving Passivhaus for such a small, detached house is inherently challenging. Passivhaus requires exceptionally low energy consumption ‘per m2’ of useable floor area. It is therefore much easier to meet the target where the form factor – that is the ratio of external surface area to useable floor area is low. Very small homes don’t generally do us that favour.

It can also be noted that where a small house comprises more wall, floor and roof for every M2 of floor area than a larger one, overall costs per m2 tend to be skewed unfavourably

But embodied C02, and overall energy consumption is of course lower the smaller a house gets, so making it bigger just to achieve certification would be illogical, and to their credit, was never an option for our clients.

We knew then that the performance of the fabric needed to be exceptional, and the method of construction would need carefully thought through to meet the brief.

We were lucky in this case, to find through site investigation that the ground conditions were favourable, and therefore concrete free foundations would be feasible. Our structural engineers (George and Angus at Element structures) were very engaged with the design intent, and have worked hard to help us develop a design to meet the brief, while remaining mindful that overly costly solutions would be unworkable.

An entirely timber superstructure, clad in buff brick with lime mortar, is supported on a limecrete strip-footing. The solid ground floor comprises foamglass aggregate and lime screed, and roof/wall insulation will be warmcell, recycled paper, pumped into the cavity between structural members. We are currently exploring options for interior finishes which avoid the use of gypsum-based products, without the associated cost that specialised eco-materials sometimes carry

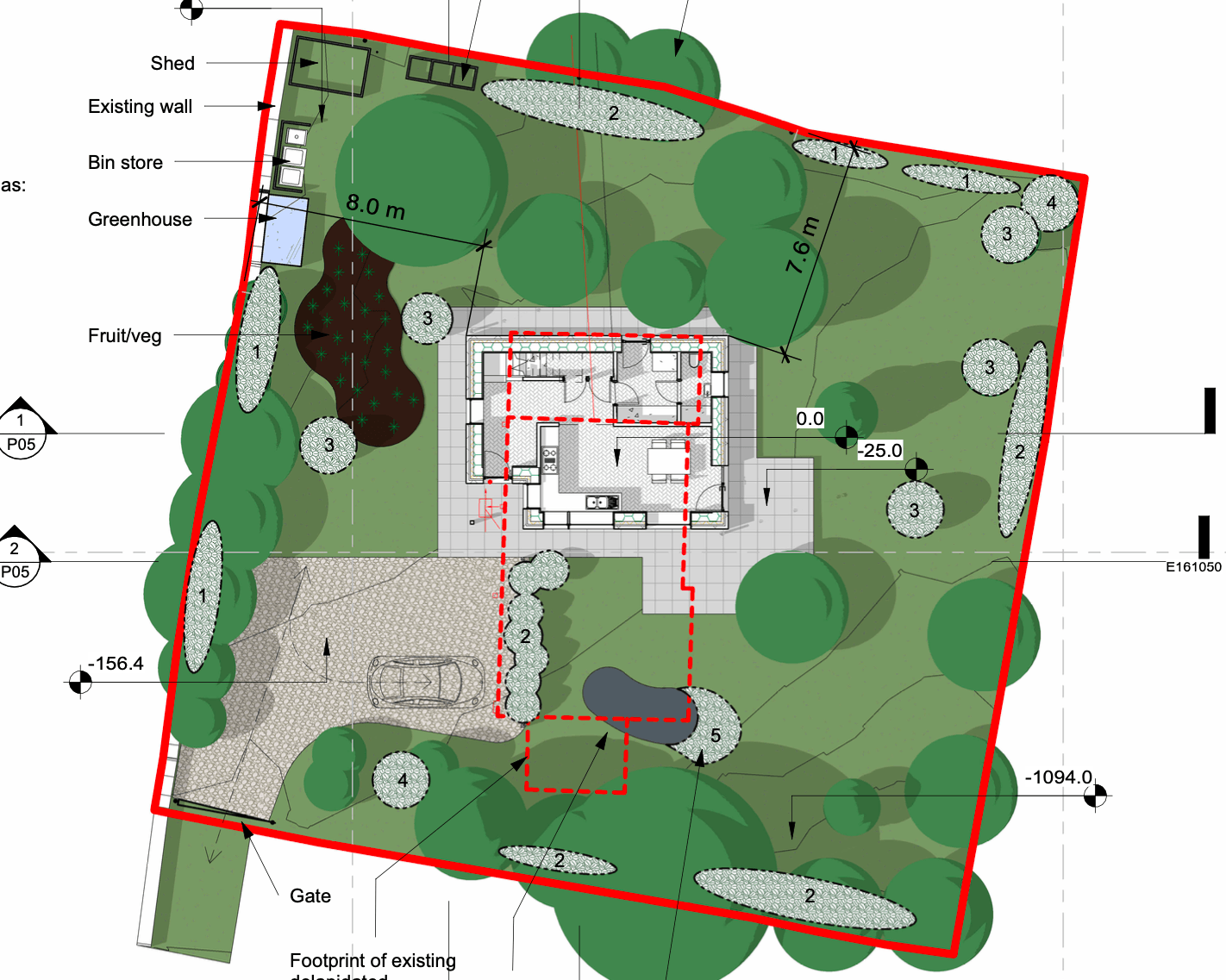

Initially the client was keen to explore ‘upside down’ layout, with living spaces on first floor in order to enjoy the views. However it was our feeling that given the large and surprisingly private garden space surrounding the property, that approach would lead to a sense of disconnect between the living spaces and the surrounding exterior spaces.

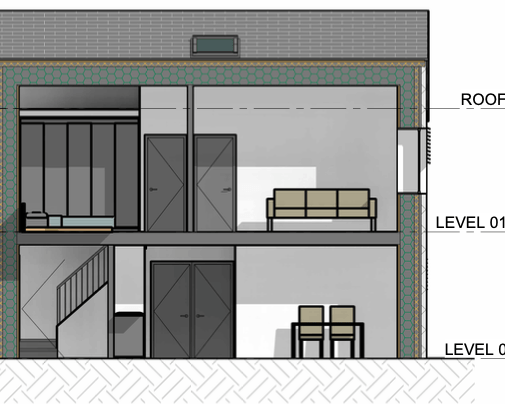

In the end a hybrid design was developed, with open plan kitchen/dining space on ground floor, with a single bedroom and living room (doubling up as an occasional guest bedroom) on first floor.

Contrary to what might be typical in ‘contemporary’ design, the clients were not looking for large expanses of glazing, complex or automated equipment, or extensive external works.

Rather the focus was on achieving elegant simplicity, un-fussy, durable design. Hardwearing, low maintenance materials, and a design that while contemporary in aesthetic, also spoke to the local prevalence of cut Bath stone.

We anticipate planning permission to be granted in the coming weeks, and look forward to completing the technical design, Passivhaus modelling and project planning. Aiming to break-ground in the autumn of this year.